EnglishNews

B&R presents solutions to supercharge battery production at The Battery Show 2024

At The Battery Show Europe 2024 in Germany, B&R will show how eliminating stop-and-go traffic in battery production lines can transform them into perfectly orchestrated, ultra productive production network

How to build a battery production superhighway

At The Battery Show Europe 2024 from June 18-20 in Stuttgart, Germany, B&R will show how eliminating stop-and-go traffic in battery production lines can transform them into perfectly orchestrated, ultra productive production networks. Visitors to Booth G67 in Hall 9 will learn how intelligent automation and track-based transport can help battery producers master the balancing act between high productivity, compact footprint and maximum availability.

“As electric vehicles come into their own, the race is on for battery producers to meet the sharp in-crease in production capacity while also managing the challenges of cost, quality and innovation,” says B&R CEO Joerg Theis. “We’re talking about orders-of-magnitude difference in cycle time com-pared to traditional automotive components – and to a large degree, the answer will come down to how intelligently battery production is automated.”

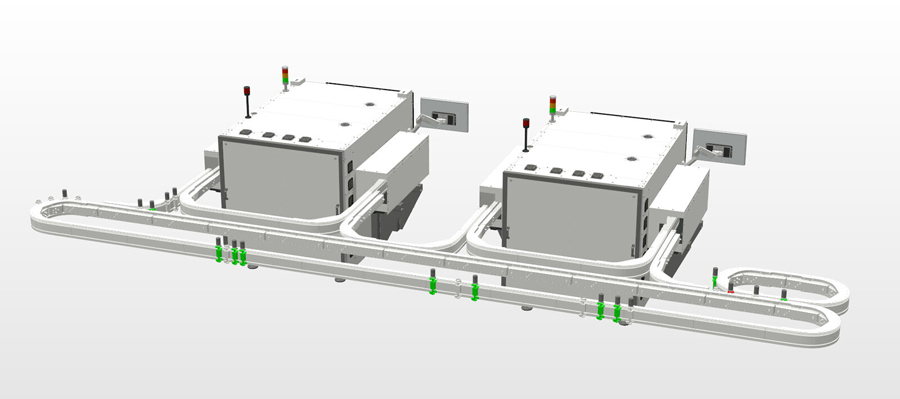

The backbone of B&R’s solutions for battery production is formed by its intelligent product transport systems. By moving each battery cell independently with variable speed, spacing and processing, it becomes possible to accelerate individual production steps by as much as 90%. Visitors can see live how B&R’s product transport systems, Codian robot mechanics and machine vision cameras all work together seamlessly. Hard real-time synchronization enables high-precision processing while the products remain on track and in motion at up to 5 meters per second.

B&R experts are on hand to discuss how battery production can benefit from powerful new capabilities such as seamless interlinking between the track system and conventional conveyors, high-precision transport of larger payloads such as prismatic cells, and new deep learning capabilities in B&R’s machine vision cameras.

Visitors will also learn about the latest evolutions in some of B&R’s flagship products: The new 4100 and 3200 series of its Automation PCs bring big steps in performance and scalability, while a major update to the B&R engineering environment, Automation Studio 6, offers a new level of collaborative, user-focused engineering across the full machine lifecycle.

100% inspection at 100% speed – With B&R and Exacom

The Open Tech Forum being held during the Battery Show features more than 20 panel discussions and live demonstrations. On Tuesday, June 18th B&R and Exacom will show how B&R’s ACOPOStrak transport system helps Exacom integrate cutting-edge X-ray inspection into battery production at full speed.

모빌리티(Mobility)의 미래 비즈니스 전략을 찾다

- 모빌리티타임즈 (mobilitytimes.net)

-

Opinion2개월 ago

Opinion2개월 ago[테크 칼럼] 굿바이 오일, 헬로 모터… 아틀라스가 ‘혈관’을 버리고 ‘신경’을 택한 이유

-

News2개월 ago

News2개월 ago“실험실 박차고 나온 아틀라스”… 현대차그룹, 로봇을 인류의 ‘동반자’로 선언

-

Features2개월 ago

Features2개월 ago차 안을 ‘빛의 캔버스’로 바꾼 아우모비오

-

Features1개월 ago

Features1개월 ago[기획] 자율주행 레벨 3 전환 앞당기는 차세대 반도체 기술을 만나다

-

Features2개월 ago

Features2개월 ago[마켓] “자율주행의 완성은 보안”… 10조 원 시장을 선점하라, V2X 보안 패권 경쟁

-

Opinion2개월 ago

Opinion2개월 ago도로 위 ‘유령 차’가 급제동을 건다… V2X 보안, 자율주행의 아킬레스건을 막아라

-

Features1개월 ago

Features1개월 ago[칼럼] 보쉬, 모빌리티의 본질을 묻다… “가장 인간적인 피지컬, 가장 정교한 디지털 AI”

-

Features1개월 ago

Features1개월 ago[심층리포트] 현대차그룹 메타플랜트 아메리카(HMGMA)와 휴머노이드 로봇 도입 전략